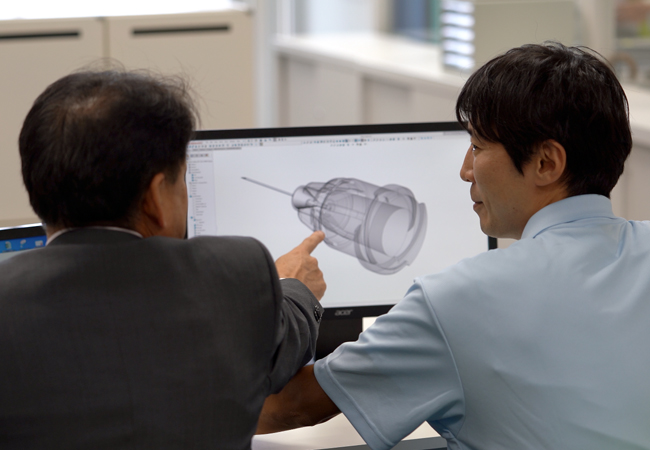

Looking for specific needle innovation or complete medical device solution? TSK Laboratory International also facilitates made to measure projects.

As an Original Equipment Manufacturer (OEM), we are a complete provider of high-quality custom-design medical devices. We are the expert in the field of needle production and we are well known as the complete solution provider, helping the customer to design and manufacture the product from steel to finish.

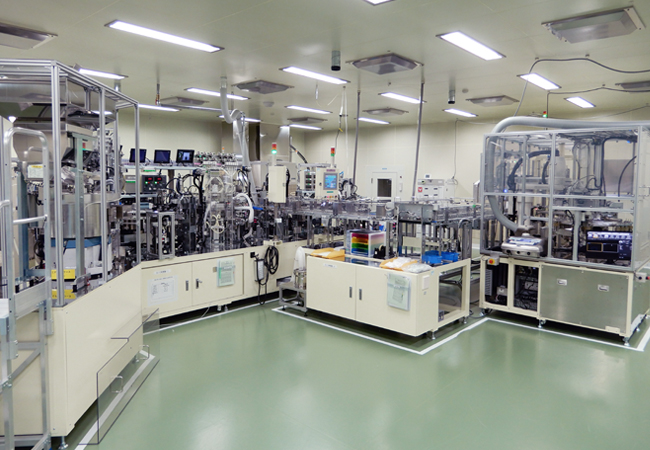

Having the option to use manual, semi-automated and fully automated production lines we can quickly adapt to different production needs from the customer.

| TSK Laboratory International ©

| TSK Laboratory International ©